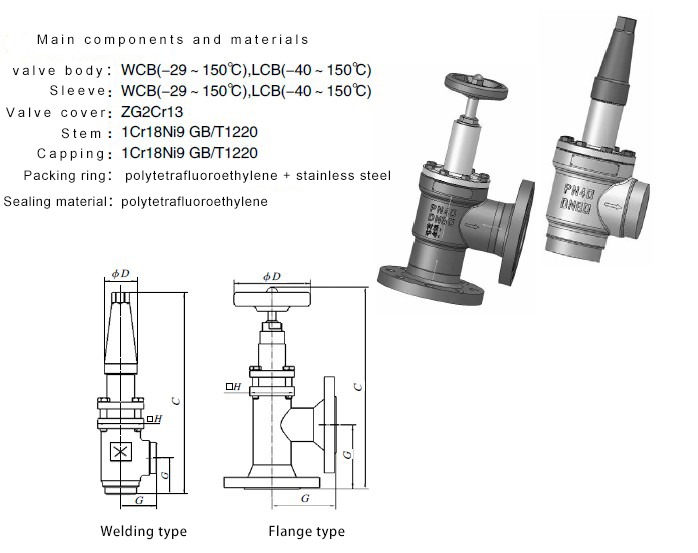

brief introduction

The stop check valve has the functions of reverse automatic check and forward manual cut-off. It can be used in various fields of industrial refrigeration. The valve has the best flow condition. The unique design of the valve core makes the valve have reliable sealing performance.

main features

1, opening pressure differential is small, only 0.001MPa;

2. A shock absorber is provided to prevent surge of the valve when the refrigerant flow rate through the valve is low or the density is low.

3, the design is lightweight, easy to assemble and disassemble, easy to maintain.

4. Cut-off check valve has back sealing function (manual rod rotates to closed state, valve seal), which can replace the filling box of the valve when the system is running;

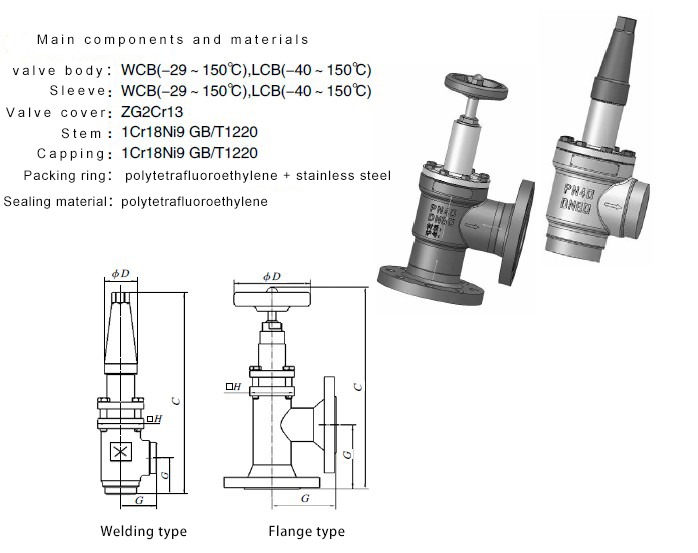

5, flexible and reliable action to ensure that the valve can be opened / closed quickly.

6, the sleeve adopts the V type flow passage, so that the valve has excellent regulating performance.

7. The middle bolts are made of stainless steel bolts.

8, sealing materials choose Teflon, so that the valve has reliable sealing performance when it is closed.

Main technical parameters

1, nominal pressure: 4MPa;

2, minimum opening pressure: 0.001MPa;

3. Working medium: refrigerant-R717 (NH3) and other non-flammable refrigerants; non-corrosive gas or liquid;

4, medium temperature: -40 ~ +150 C;

5. Leakage when closing valve: 0ml/h;

6, seal form: soft seal (PTFE);

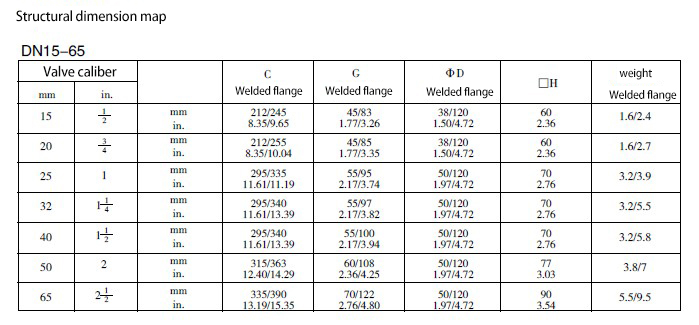

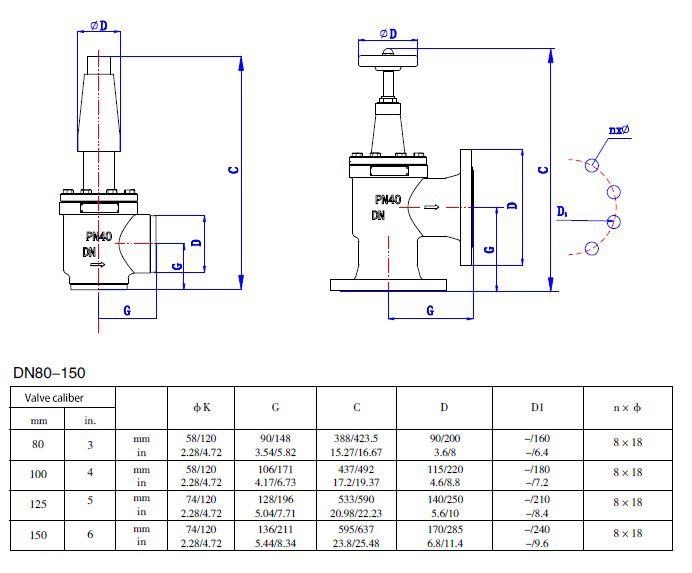

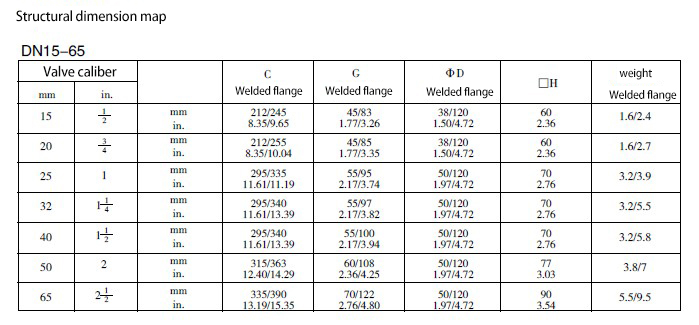

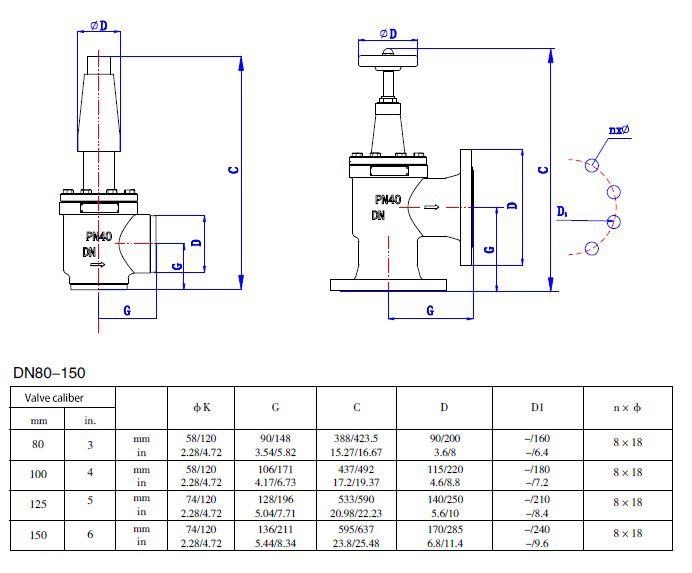

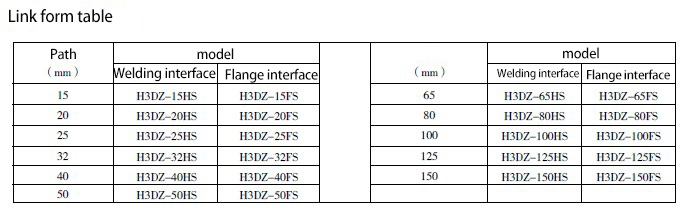

7. Pipeline connection mode: welding connection, welding groove according to EN10220 standard, flange connection, flange size according to HG20592 standard;

8. Packing letter: Packing letter consists of an O-ring and an energy storage seal ring, which ensures the sealing of the valve in the temperature range of - 40 ~150 ~C.

9, stem: stem material is stainless steel, with O ring to achieve the best sealing effect.

10, spool: PTFE sealing material, so that the valve has the most reliable sealing performance when it is closed. A metal flange is installed around the sealing pair to protect the sealing pair from high pressure damage.

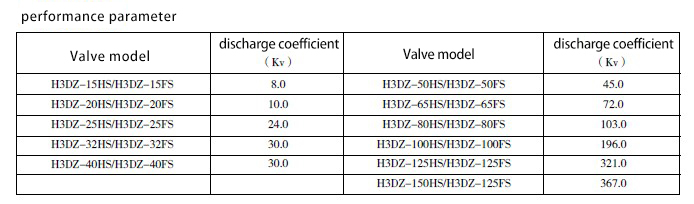

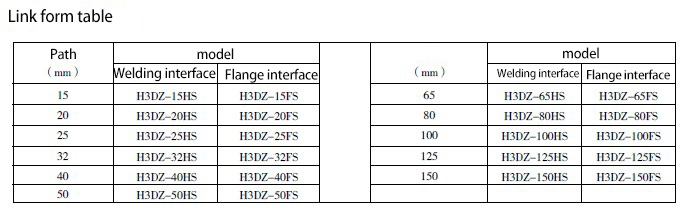

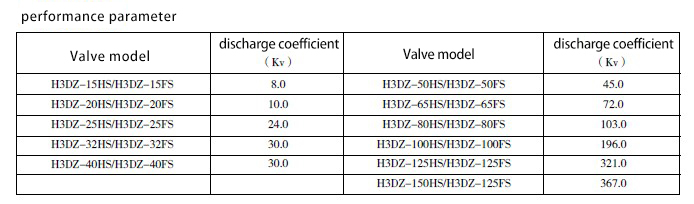

11, valve performance parameters