ZHPS high-pressure single-seat regulating valve is one of Cv3000 series products, which can control high-pressure fluid at different temperatures extensively.

main features

Equipped with multi spring film actuators, compact structure and high output power.

The valve core adopts the upper guiding structure with large guiding area, good vibration resistance and cavitation corrosion.

The fluid channel is S streamlined, with low pressure drop loss, large flow rate and wide adjustable range.

Main technical parameters

Valve body

Type: straight through single seat casting ball valve

Nominal access: DN25, 40, 50, 80mm

Nominal pressure: ANSI 900, 1500, 2500 JIS 63K

Connection type: flange connection RF, RJ

Flange standard ANSI B16.5-1981, JIS B2201-1984

Welding connection with 25~80mm (80mm).

Materials: cast steel (WCB), cast stainless steel (CF8, CF8M), titanium (Ti), etc.

Upper valve cover: normal temperature (P) -5 ~ +230 C

Elongation type I (E I) +230 ~ +566 C

Note: the working temperature should not exceed the allowable range of all materials.

Gland type: bolt compression type.

Packing: V type polytetrafluoroethylene, impregnated polytetrafluoroethylene asbestos, asbestos braiding, graphite packing.

0 valve components

Spool type: upper guide single seat plunger spool

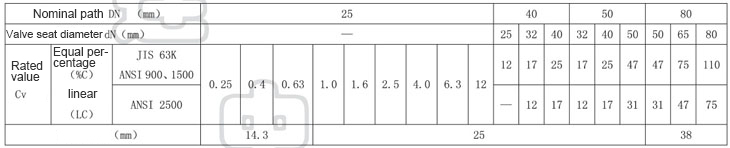

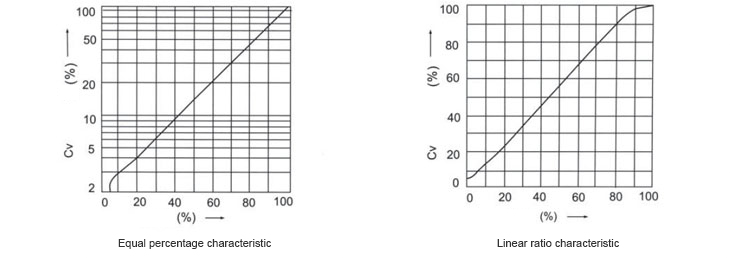

Flow characteristics: equal percentage characteristics (%C), linear characteristics (LC)

Materials: stainless steel (304, 316, 17-4PH, 9Cr18, 316L), stainless steel surfacing Stellay alloy, titanium (Ti) and

Corrosion resistant alloys, etc.

Executive agencies

Type: LHA multi spring type thin film actuator, LVA5 single spring type film actuator.

LVA6 single acting cylinder piston actuator and LVP double acting cylinder piston actuator

Diaphragm material: LHA, LVA5 type ethylene propylene rubber, nylon cloth, NBR nylon cloth.

Spring range: 20~100, 40~200, 80 ~ 240kPa (type LHA, LVA5)

190~250, 190 ~ 300kPa, 190 ~ 350kPa (LVA6 type)

Air supply pressure: film actuator LHA type (260 ~ 400kPa) LVA5 type (140 ~ 280kPa)

Piston actuator LVA6 type (280 ~ 400kPa), LVP type (300 ~ 500kPa)

Air source connector: Rc1/4

Ambient temperature: -30 ~ +70 C

Valve action type: positive actuator realizes valve's gas-close type, reaction actuator realizes valve's gas-open type

0 performance

Leakage: meet standard ANSI B16.104-1976 grade IV, less than 0.01% of rated Cv.

Return error: 1% with locator less than full stroke.

Basic error: + 1% with locator less than full stroke.

Note: Standard V PTFE packing is adopted.

Accessories: positioner, air filter pressure relief valve, stroke switch, retaining valve, valve position conveyor, handwheel mechanism, etc.

Adjustable range: 50: 1

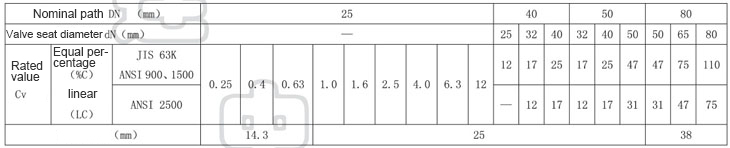

0 Cv value and stroke

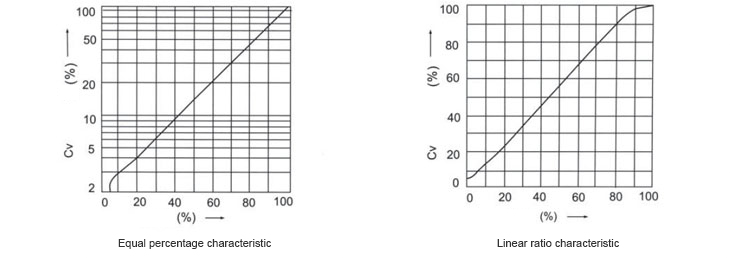

Typical flow characteristic curves

Flow characteristic curve

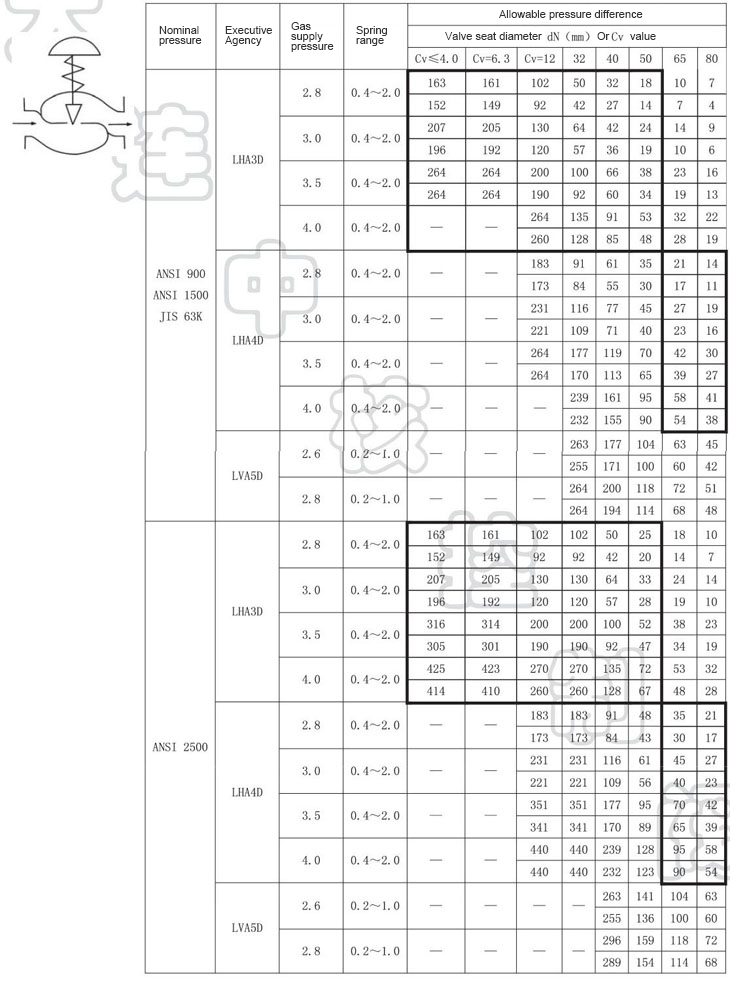

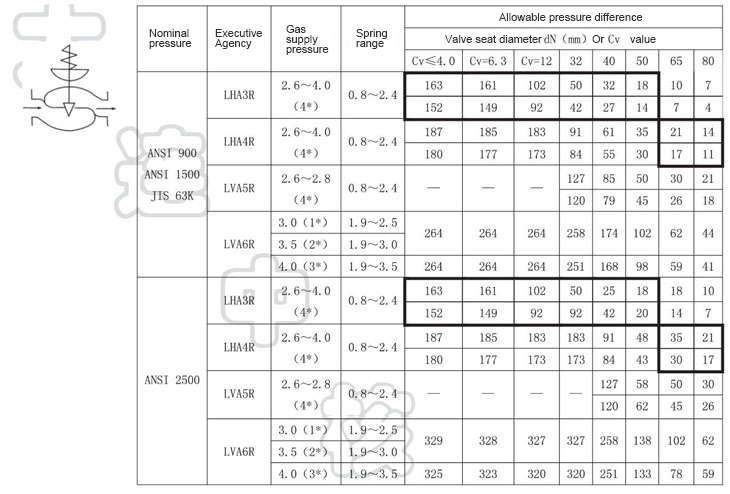

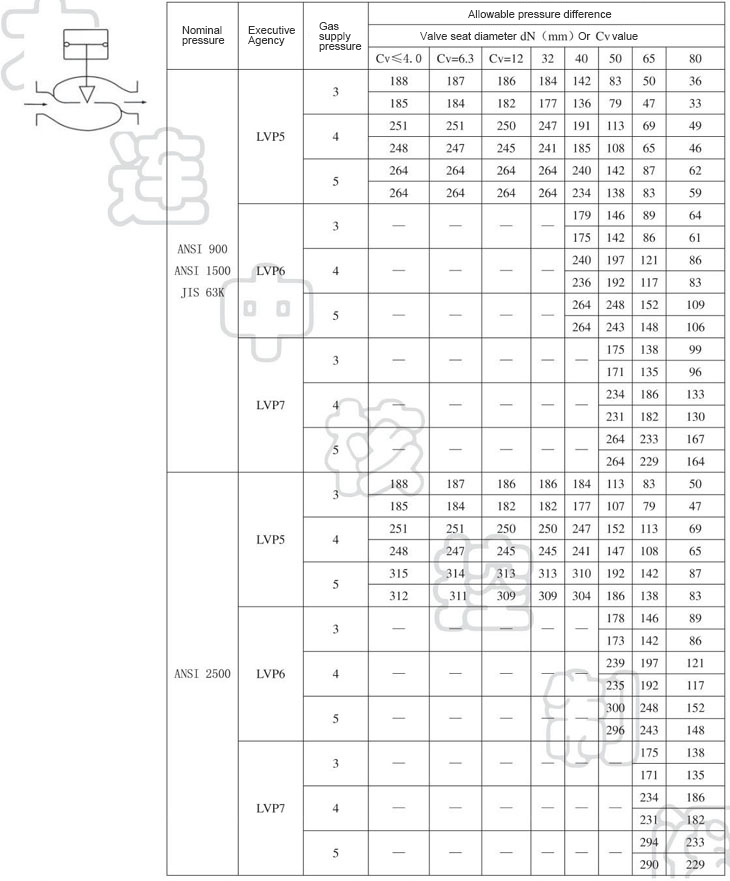

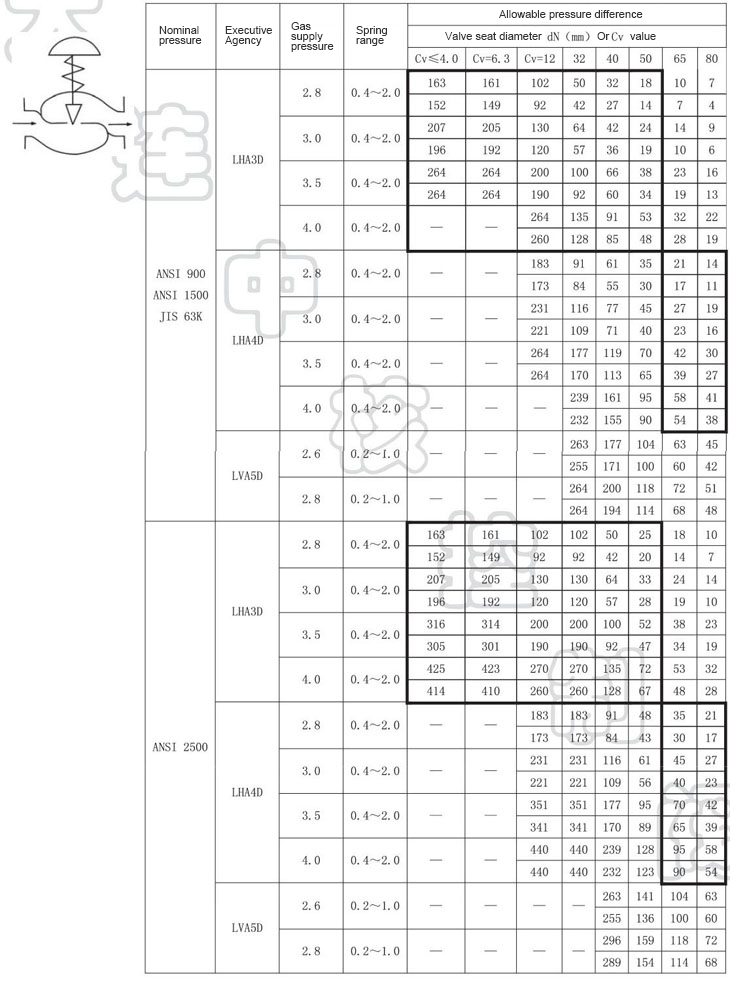

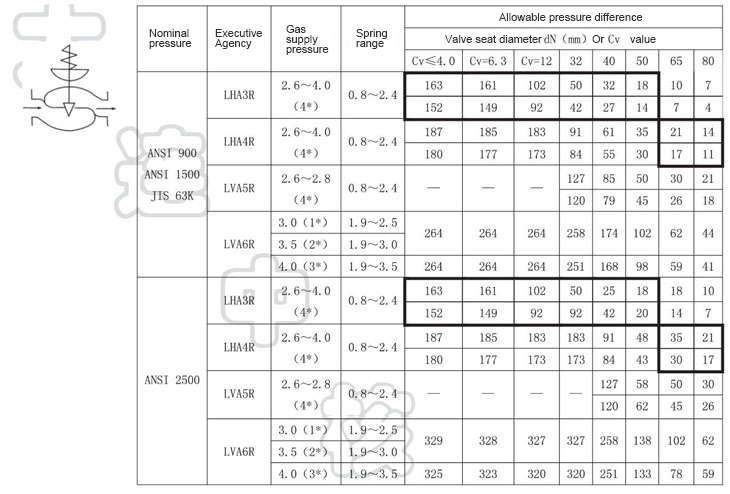

Allowable pressure difference

I. LHA or LVA actuators for valves

A. gas shut valve 100kPa

B. gas open valve 100kPa

Note: maximum allowable pressure difference shall not exceed the maximum working pressure specified in ANSI B16. 34 - 1981 standard.

The inlet pressure P1 shall not exceed the maximum allowable pressure difference when the valve is closed.

Maximum allowable pressure difference varies with seat leakage. The number above the same cell indicates that seat leakage is less than Cv value.

0.01%, the lower figure indicates that the leakage of the valve seat is less than 0.001% of the Cv value.

* 1* is only used for valves of nominal diameter 25mm and Cv=0.25~0.63.

2* is only used in valves of nominal diameter 25mm, Cv=1.0~12 and nominal diameter 40~50mm.

3* is only used in nominal diameter 80mm

4* supply pressure

- digital control mechanism for digital control of valves in black frame

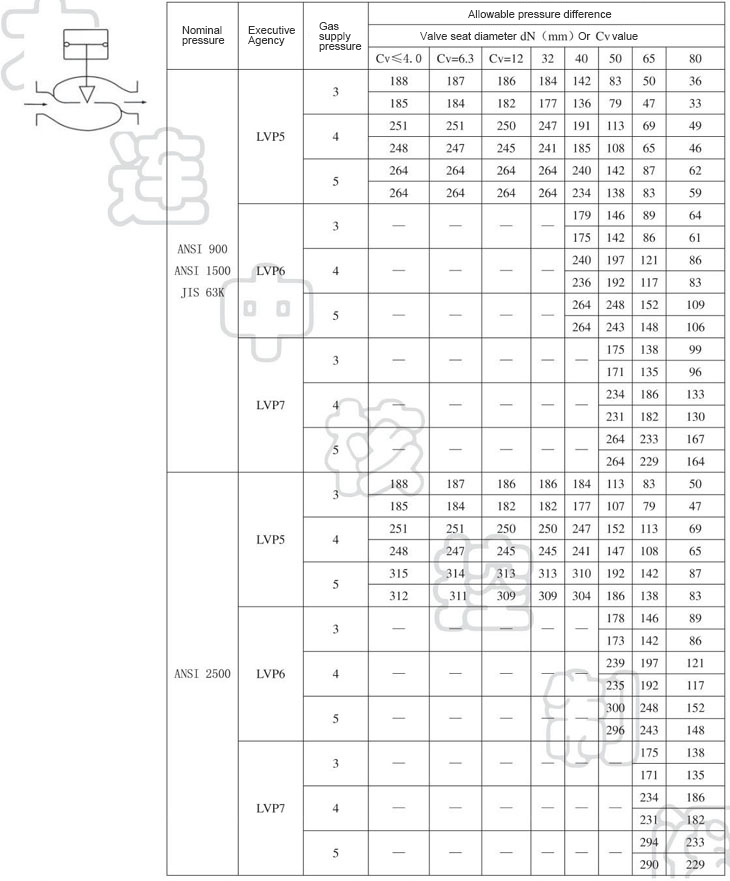

II. Valve equipped with LVP actuator 100kPa

Note: If the actuator has an auxiliary gas source, the smaller one of the two should be selected as the basis for calculating the allowable pressure difference.

Maximum allowable differential pressure shall not exceed the maximum working pressure specified in ANSI B16.34-1981 or JIS B2201-1984 standards

The inlet pressure P1 shall not exceed the maximum allowable pressure difference when the valve is closed.

Maximum allowable pressure difference varies with seat leakage. The number above the same cell indicates that seat leakage is less than Cv value.

0.01%, the lower figure indicates that the leakage of the valve seat is less than 0.001% of the Cv value.

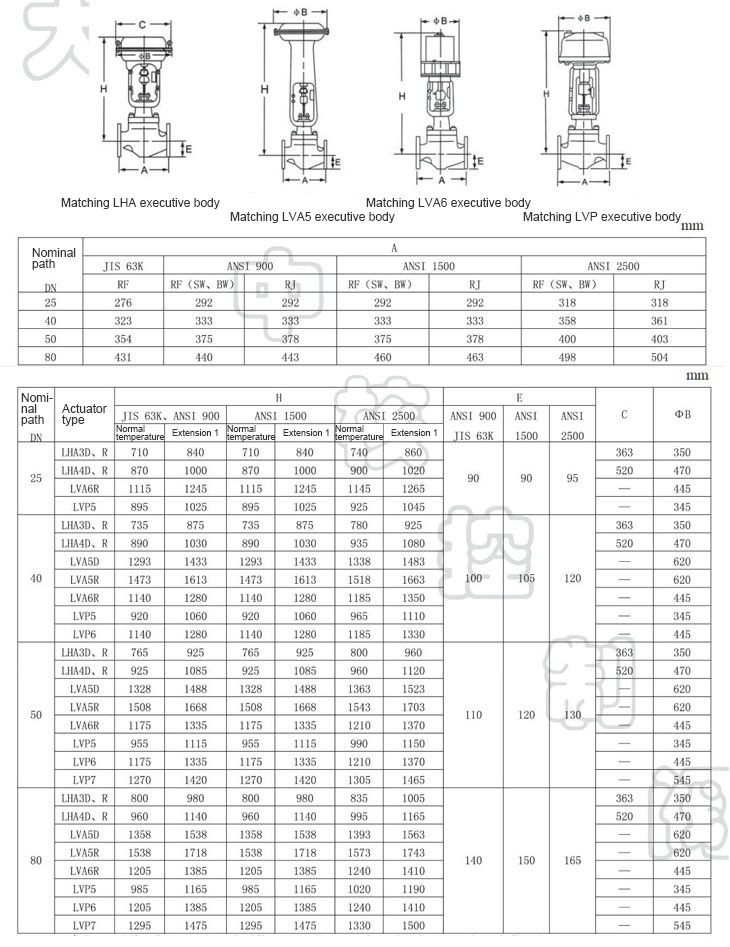

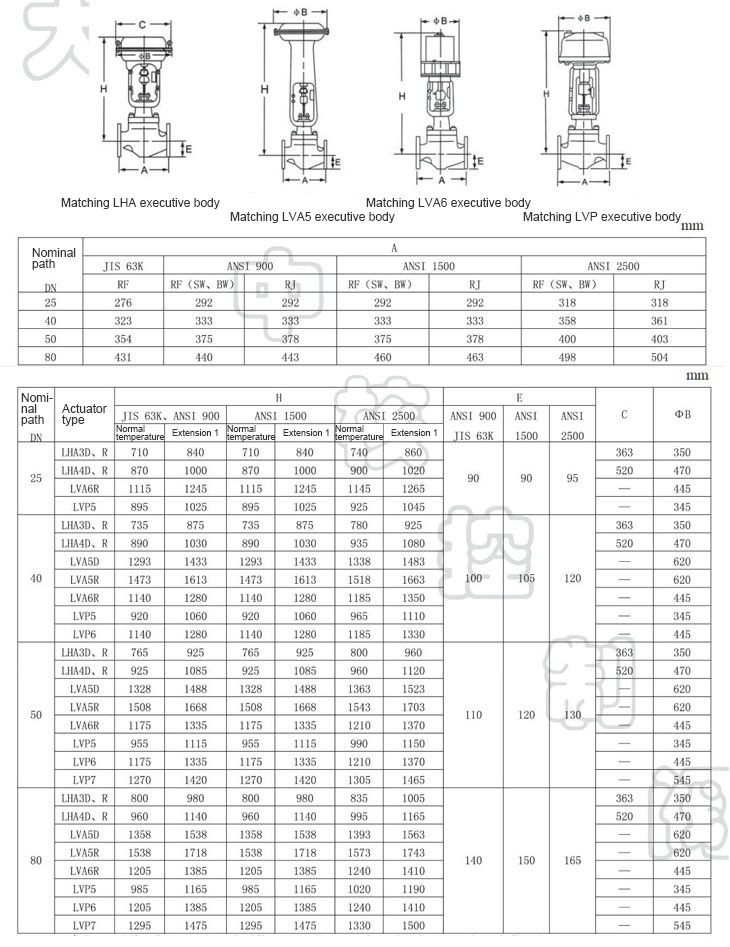

Shape connection dimensionmm

Note: The H dimension in the table is the number when the control valve is not equipped with handwheel mechanism. If the handwheel mechanism with top mounting is equipped, the size of handwheel mechanism should be added accordingly.

Weight kg

Note: the number in brackets is the weight of the nominal pressure JIS 63K valve.