Causes and troubleshooting of solenoid valves for refrigeration:

1. when the solenoid valve is open, short circuited or burned, the valve core can not be absorbed, causing the slider not to act. It should be replaced.

2. the solenoid valve of the refrigeration valve is stuck, and the valve core can not act, causing the slider to not move. The valve body can be cleaned and adjusted.

3. When the power supply voltage is lower than the rated value of the refrigeration solenoid valve, the pressure difference between the inlet and outlet of the solenoid valve exceeds the opening capacity. At this time, the valve often emits "beep" noise, which causes the valve core not to close. Power supply should be improved.

4. the solenoid valve used for refrigeration is reversed, causing the valve not to move. Flow direction should be adjusted.

5. the system has high temperature, high pressure and impurities in the machine, resulting in deformation and clamping of the slider. It should be replaced.

6. remanent suction valve core or valve heart is stuck, after the power failure, the solenoid valve can not be closed. Cleaning adjustment, such as no effect replacement.

7. refrigerant solenoid valve gasket damage or fastening screws loose, causing refrigerant leakage. Change the gasket and tighten the screws.

8. the capillary on the valve is blocked or broken, or the serious leakage of the system causes the slider to not act. Clean the capillary or weld the copper tube slightly thicker than the broken capillary tube.

The 9. valve is dirty, valve seat or valve pin damaged and spring force is too small, resulting in electromagnetic valve closes lax. Clean and adjust or replace springs.

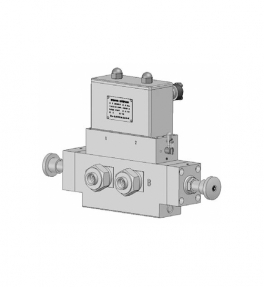

In addition, if the internal leakage of the reversing valve causes the leakage of high-pressure refrigerant gas to the low-pressure side, and the normal pressure can not be established at both ends of the piston of the reversing valve, the reversing valve should be replaced. If the pressure difference of the refrigeration system is too large to make the reversing valve reversible, it is necessary to check the pressure of the refrigeration system or find the leakage point, and fill the refrigerant. If the slider of four-way valve does not move or does not move properly, the screwdriver wooden handle can be used to check and judge, tap the valve body gently, and turn on or off the AC 220V power supply from time to time. Repeat several times. When the armature absorption sound and the gas reversing sound in the valve body are heard, the reversing valve can be basically restored to normal work.